In the world of modern logistics, packaging, and recycling, Bonded Cord Strapping is proving to be an essential tool for businesses that need strength, flexibility, and reliability in their bundling operations. Created from a unique type of high-tensile polyester, bonded strap is engineered for performance and safety—making it ideal for a wide range of demanding applications.

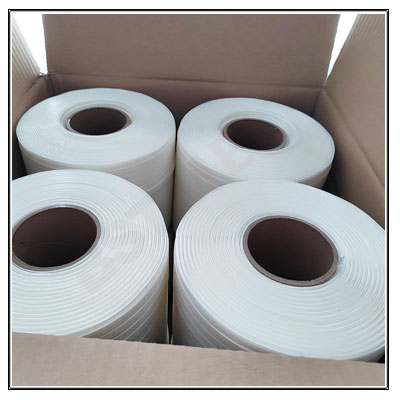

Unlike traditional strapping options such as steel or rigid plastic, bonded cord strapping is made using a special bonding process that fuses multiple polyester filaments together. This process results in a durable, lightweight, and flexible strap that offers high system strength without compromising ease of handling. Its combination of resilience and user-friendliness makes it especially suitable for heavy-duty loads, large bundles, and irregularly shaped items.

Available in a variety of widths and lengths, bonded cord strapping is widely used across multiple industries including recycling, construction, agriculture, warehousing, and logistics. One of its most common applications is in the baling of waste paper and cardboard—where a reliable, strong, and safe bundling material is essential to maintain compact bales for transport and recycling.

Thanks to its high resistance to impact and its ability to absorb shock, bonded strap performs particularly well in environments where products may shift or settle over time. It offers excellent holding force while being soft on both users and packaged goods, minimizing the risk of injury or damage. Unlike steel strapping, it does not snap or recoil under tension, which enhances workplace safety significantly.

In addition to waste management and baling, bonded cord strapping is also used for securing building materials, lumber, piping, and heavy equipment. Its high break strength and stretch resistance make it ideal for stabilizing large loads during transport, especially in rough handling or long-haul shipping conditions. For the agriculture and landscaping sectors, it’s an excellent option for bundling pallets of supplies, securing tools, or tying down harvested products.

The ease of use is another major advantage of bonded strapping. It can be applied using simple manual tensioners and sealed with buckles—no need for heavy-duty machinery. This reduces labor costs and makes it ideal for fieldwork or mobile operations where access to powered tools may be limited.

What’s more, bonded cord strapping is resistant to moisture, UV exposure, and chemicals, making it a great choice for both indoor and outdoor applications. It maintains its strength in extreme weather conditions, offering year-round performance in various environments.

As sustainability becomes a growing concern, bonded cord strapping also contributes positively. Many manufacturers now produce bonded straps using recyclable polyester materials. Additionally, its lighter weight compared to steel results in lower transportation emissions and easier disposal.

With its combination of strength, flexibility, safety, and environmental advantages, bonded cord strapping is quickly becoming the go-to choice for packaging professionals looking to improve efficiency without sacrificing performance. Whether it's securing a bundle of cardboard for recycling or stabilizing a load of construction materials on a pallet, this innovative strapping solution is setting new standards in modern load containment.

Others News

Bonded Cord Strapping: The Multifaceted Solution for Securing and Bundling Across Industries

Bonded Cord Strapping: The Multifaceted Solution for Securing and Bundling Across Industries Innovative Bonded Cord Strapping Revolutionizes the Industry

Innovative Bonded Cord Strapping Revolutionizes the Industry Bonded Strapping Revolutionizes Waste Baling and Protection of Goods

Bonded Strapping Revolutionizes Waste Baling and Protection of Goods Bonded Cord Strapping: The Versatile Packaging Solution Revolutionizing Transportation

Bonded Cord Strapping: The Versatile Packaging Solution Revolutionizing Transportation