As global recycling initiatives continue to expand, the efficiency and safety of materials handling have become top priorities for businesses and waste management facilities. Among the many tools used in modern recycling processes, bonded strap is gaining increasing attention for its cost-effectiveness, safety, and strong performance in tying smaller bales of recyclable materials.

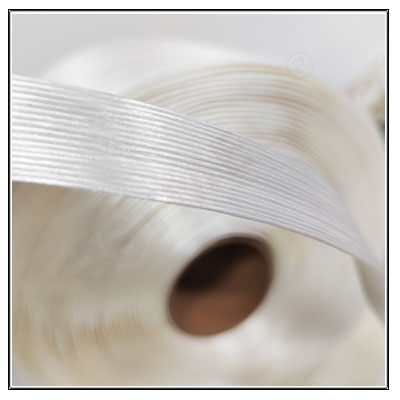

Bonded strap—also referred to as bonded baling tape—is a synthetic strapping solution commonly used for securing light to medium-density bales, particularly those composed of cardboard, soft plastics, and similar waste materials. Unlike steel or heavy-duty polyester strapping, bonded strap is lightweight, easy to handle, and specifically engineered for smaller bale applications. Its design makes it a favorite among operators who need an efficient, reliable, and safe option for bundling recyclable materials.

One of the key advantages of bonded strap is its impressive strength-to-weight ratio. Despite being light and easy to manage, it offers high, guaranteed breaking strengths that ensure bales remain secure during storage, transport, and processing. This makes it an ideal solution for small and medium-sized recycling operations that handle a steady flow of baled waste but may not require the rigidity of heavy-duty alternatives.

Safety is another major benefit of bonded strap. Unlike metal strapping, which can snap back dangerously or cause injury from sharp edges, bonded strap is much safer for both the baler operator and the end receiver of the bale. Its smooth, flexible surface reduces the risk of cuts and handling accidents, making it a preferred choice in environments where worker safety is paramount.

From an operational standpoint, bonded strap is easy to feed through balers and simple to tie off manually or with tensioning tools. This ease of use can significantly speed up baling procedures, especially in facilities where high throughput and quick turnaround times are required. Operators appreciate its minimal training requirements and low-maintenance nature, which help keep workflows smooth and efficient.

In terms of cost, bonded strap offers significant advantages over other strapping materials. Its relatively low price point—combined with its strength and reliability—makes it one of the most economical solutions for small bale applications. Facilities can reduce their material costs without sacrificing the integrity or safety of their bales. Additionally, many bonded strap options are made from recyclable or reusable materials, supporting environmentally conscious waste handling.

Bonded strap is also highly versatile. While it excels in packaging bales of cardboard and plastics, it can also be used for textiles, paper, foam, and other compressible recyclables. Its adaptability makes it a valuable all-purpose tool in waste management facilities, distribution centers, and small-scale recycling programs.

Choosing the right bonded strap involves evaluating the size and weight of the bales, the pressure exerted by the baler, and the type of recyclable material. Suppliers typically provide break strength ratings and usage recommendations to help buyers make informed decisions. As always, partnering with a reputable strap manufacturer or distributor ensures consistent product quality and access to expert advice.

In conclusion, bonded strap is a practical, safe, and budget-friendly solution for tying smaller bales in recycling operations. It provides high performance without the risks or costs associated with heavier strapping materials. For businesses aiming to streamline their waste handling while prioritizing safety and sustainability, bonded strap offers a smart and reliable alternative.